Custom Quote Request Form

Custom Printed Boxes

FAQ'sSpecification Learn More Reviews |

||||||||||||||||

|

Q: Is there a minimum order quantity for custom printed box?A: No, there is no minimum order for custom printed box. You can order as few boxes as you like. Ordering a few boxes is perfect if you would like a sample to check out before committing to a larger order. However, due to initial costs involved in setting up a print job, ordering bigger quantities will typically result in a lower per unit cost. Your account representative can help you find the most efficient solution in order to keep your total project costs low. Q: How do I measure the length, width, and height of my custom printed box?A: With the box open toward you, here is how to get the correct measurements for the inside of the box: The length is measured from the left to right side of the box. Q: Which parts of the custom printed box can I customize?A: All sides of the custom printed box are fully customisable — front, back, top, bottom, outside, and inside. The inside can be printed for an additional charge. You can customize both the outside and inside (even the flaps that tuck away or reside inside the folded box). Please work with your account representative to discuss any specific requirements. Q: The proof for my custom printed box looks blurry. Will it print that way?A: No. The emailed proofs only show how the graphics align on the box. The final print is much sharper, as long as vector or high-resolution graphics have been used in your design file. You will be contacted if your graphics appear to be at too low a resolution. If you have any concerns, please feel free to ask us a question. Q: What is 4/0 vs. 4/4 when designing a custom printed box?A: 4/0 refers to printing full colour on one side of the printed sheet. This side represents all of the outside panels of the box once finished. On the other hand, 4/4 refers to printing full colour on both sides of the printed sheet. In this case you can customize all of the outside and inside panels of the boxes. Q: Can you send me samples of your custom printed box?A: We can send samples of our recent print orders. Please submit a sample request and our sales representative will be in touch so that appropriate product box samples can be sent. Q: What styles or types of boxes can Printingblue produce?A: We can produce many different standard styles of boxes. In addition, we can also produce customised boxes to fit your specific requirements. Please send us the details and we will be happy to produce a free mockup for your review. Here is a list of some of the many different box types that we can produce: Q: Which industries do you serve?A: We have worked with clients from a wide variety of industries including but not limited to:

Q: What are the language requirements for custom-printed product boxes intended for use within Canada?A: Generally, all information printed on your custom product boxes must be truthful and not misleading. Specific industries like food, pharmaceuticals, and cosmetics have stringent regulations for labeling and packaging, as stipulated by the FDA.

Custom Printed Boxes with No MinimumsWith so many retail businesses online today, it is more essential than ever to brand your product boxes with custom printing so that your customers can recognize your brand as soon as they receive their orders. In addition, to succeed in highly saturated industries, you need to differentiate your products from your competition and custom branded boxes are a great way to achieve this goal. In order to achieve the perfect look and product fit, you will need to customize the size and shape of your retail boxes. When designing branded boxes, you can control the look, feel, and functionality of the boxes by using the right combination design elements, different textured cardstocks, and finishing coatings. A good box manufacturer can help guide you through this process by providing in depth graphic and structural design guidance. Why Businesses Need Custom Printed BoxesConsumers demand a high-quality experience at every step of the buying process, from the ordering interface to the final unboxing of the products. A custom-designed box can help you beautifully organize and display your products during the unboxing experience and help create a lasting impression on customers at the end of their purchase experience. In addition, you can also help your bottom line by devising the most efficient and secure way of packing your products in the smallest space and thus reducing the amount of required packaging while minimizing in-transit damage. Furthermore, if your products are sold from store shelves, then shoppers will likely see all sides of the packaging which can be used as advertising space to maximize sales. To maximize sales, make sure that the customers can see your:

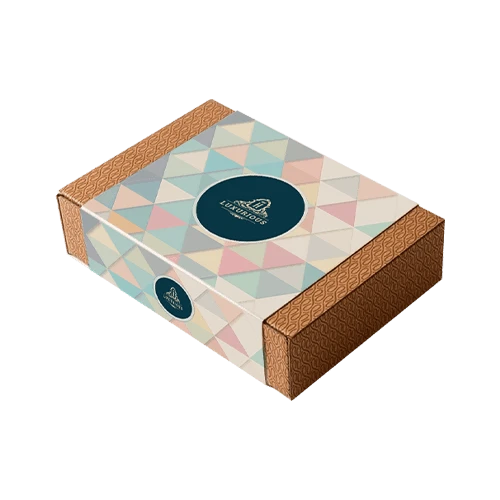

Enhancing Brand Identity Through SustainabilityWorldwide and especially in the CA, businesses are increasingly cognizant of the significant environmental impact of packaging materials and the importance of adopting sustainable practices. Businesses that use custom-printed boxes can contribute to brand identity and sustainability efforts by aligning with applicable packaging regulations and adopting sustainable practices. By doing so, these businesses can help enhance their brand identity through a demonstrated commitment to environmental responsibility. Opting for eco-friendly packaging materials like recycled cardboard and compostable materials reduces environmental impact. Sustainable packaging design practices, such as minimizing size and weight, optimizing recyclability, and using renewable energy, further contribute to sustainability efforts. It is also essential to review and adhere to specific regulatory guidelines in the markets that you operate in. For example, Packaging Waste Regulations aim to minimize environmental impact by promoting recycling and waste reduction. Businesses handling packaging materials must adhere to recycling targets and report packaging waste data to environmental agencies. Budget-Friendly Tips to Create Luxury Custom Printed BoxesCustomising custom-printed boxes to create a luxury look and feel does not have to break the bank. Here are some cost-effective tips to achieve a high-end appearance:

Incorporating cost-effective customization tips can help you transform your custom-printed boxes into luxurious packaging that enhances your brand image and captivates customers. In order to select the right finishing touches, you can request a complimentary sample kit. |